BESTONE Plastic Injection ZI de la Tuilerie, 3 rue de l’industrie - 01100 ARBENT, France | +33 (0) 474 816 406 - com@bestone-france.com

BESTONE Plastic Injection ZI de la Tuilerie, 3 rue de l’industrie - 01100 ARBENT, France | +33 (0) 474 816 406 - com@bestone-france.com

BESTONE is committed to pursuing efficiency.

All the company’s employees possess the quality tools and stated requirements from the start of a project up to delivery of the components.

BESTONE has excellent organisation and operational processes that are transparent, efficient and tried-and-tested.

BESTONE’s quality management system is certified in accordance with standard ISO 9001:2008.

Our philosophy places each employee at the heart of the company’s accountability and rigour.

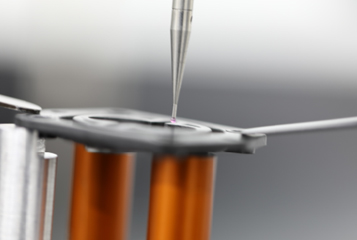

With our high level of organisation and transparent, efficient and tried-and-tested operational processes, we carry out consistent checks each day according to quality standards adapted to the product and its use, from the moment we start a development.

A design (FMEA) and process (PFMEA) risk analysis is carried out on the product in cooperation with customer product experts, followed by the application of quality statistical tools (SPC, X/R control card) for production monitoring.

Your constraints are our priority. The initial samples approved by the customer are the result of the development stages: we then guarantee the product's compliance and quality during development, which allows us to define a methodology and suitable methods of control for a high-quality and precise end result.

Every player in the production chain is responsible for the quality of the products.

Each method of production includes direct monitoring of quality and integrated statistical tools ensure that process developments, and consequently the quality of the products, are monitored as soon as production starts.

Production operators have a computerised monitoring tool which enables them to record, according to the control level: